About C103

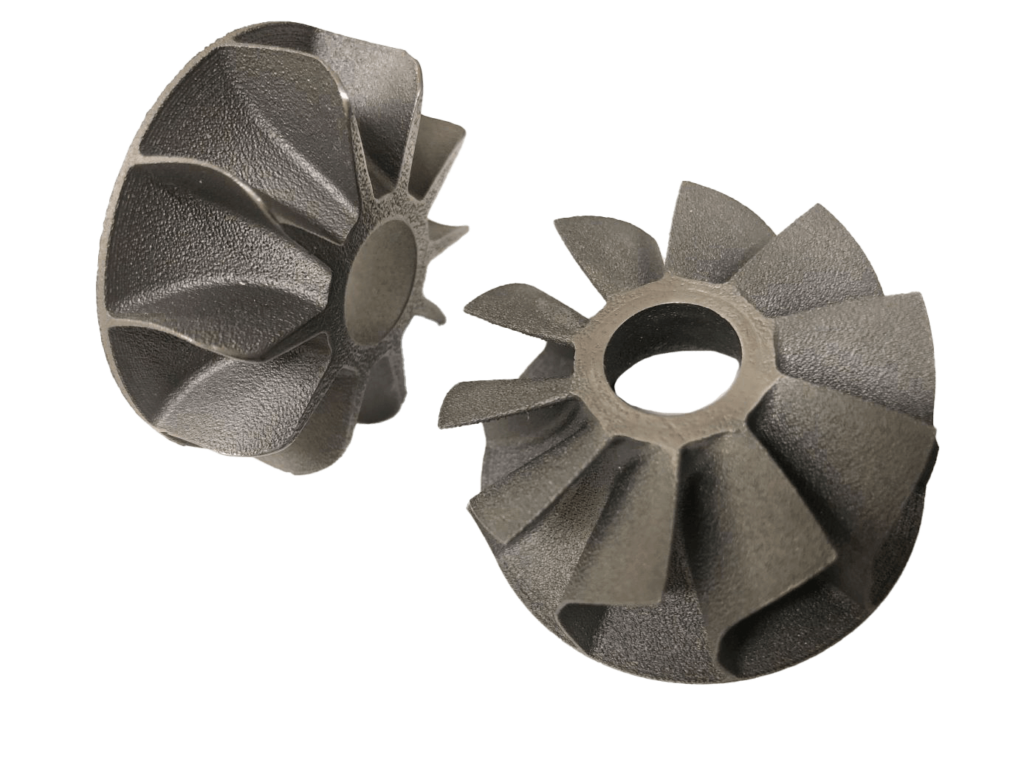

At Elmet Technologies, we specialize in the innovative production of C103, a renowned alloy composed of niobium, hafnium, and titanium. This sought-after material forms the backbone of strong rods and cutting-edge additive manufacturing powders, customized for precision 3D-printed components. With our state-of-the-art AM methods, we deliver C103 solutions, utilizing advanced extrusion and rotary forging techniques to fulfill the requirements of our diverse clientele.

Furthermore, we collaborate with respected external vendors to produce high-quality AM powders, ensuring precision and efficiency. Our expertise also extends to machining C103 rods, enhancing their applications across various industries. Contact our expert team to learn more about potential solutions.

Superior Quality for Critical Applications

- Holds strength past that up to 1500 °C

- High melting and boiling points

- Relatively low density

- High strength

- Low ductile to brittle transition temperature

- Good corrosion resistance

- Excellent room temperature ductility

- High strength at elevated temperatures

- Excellent thermal conductivity

- Low ductile-to-brittle transition temperature for cryogenic applications

C103 advanced manufacturing properties

The chemical composition of finished parts may be supplied upon request when a purchase order is placed. The chemical composition of the starting powder shall conform to the following limits:

Chemical Properties:

(Mass fraction in % [cg/g]; ppm [μg/g])

- Nb: 88% min

- Hf: 9-11%

- Ti: 0.7-1.3%

- Ta: 0/5% max

- W: 0.5% max

- Zr: 0.7% max

- C: 150 ppm wt max

- O: 500 ppm wt

Physical Properties:

| Density | Relative Density | Surface Roughness |

| 8.8 g/cm3 | 99+% | <10 μm |

Mechanical Properties:

Tensile properties can be supplied on request when a Purchase Order is placed.

C103 for Aerospace and Defense

C103 plays a crucial role in advancing the defense and aerospace industries. It enhances performance and reliability in small satellite propulsion motors, specifically in divert and attitude control (DAC) systems. Due to its superior strength and durability in extreme conditions, C103 is also key in constructing second-stage rocket motor shrouds.

Additionally, C103 is used in manufacturing afterburner plates for fighter jet engines, contributing to increased efficiency and performance. Its application in leading-edge components for hypersonic vehicles and missiles ensures structural integrity and thermal resistance. This highlights its versatility and indispensability in cutting-edge aerospace technology.

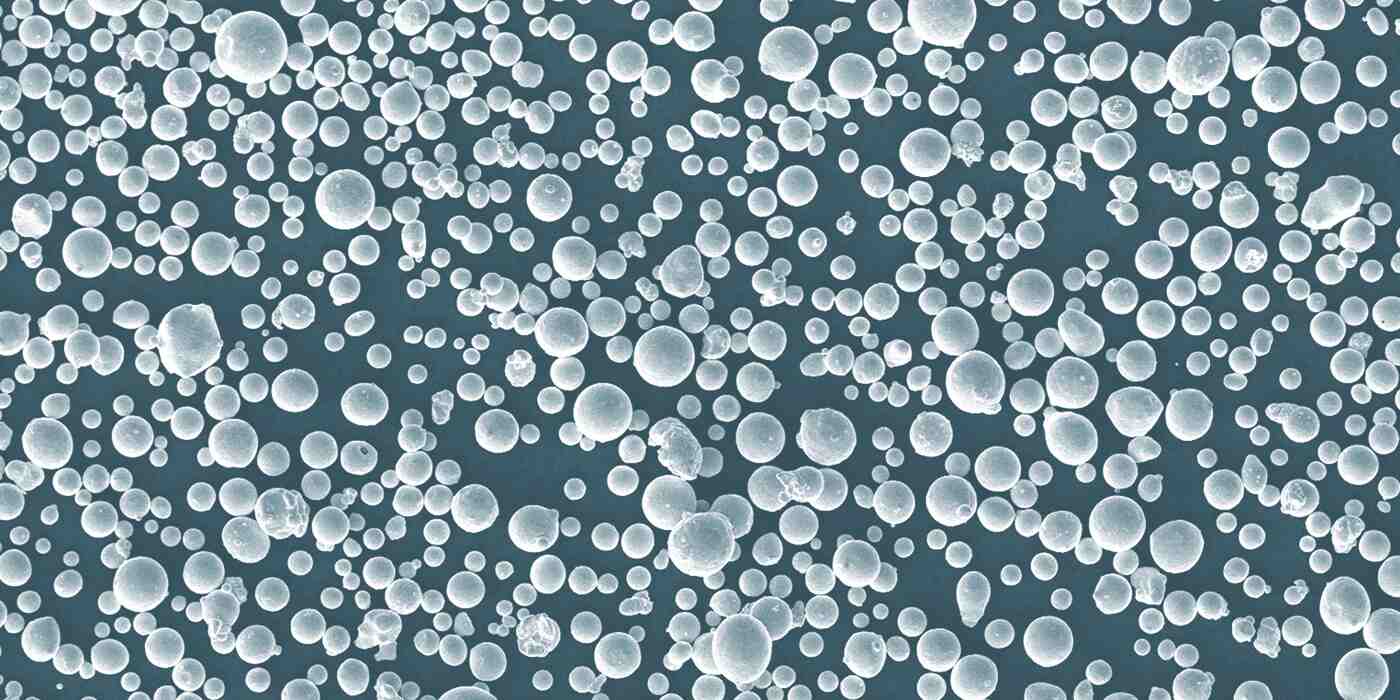

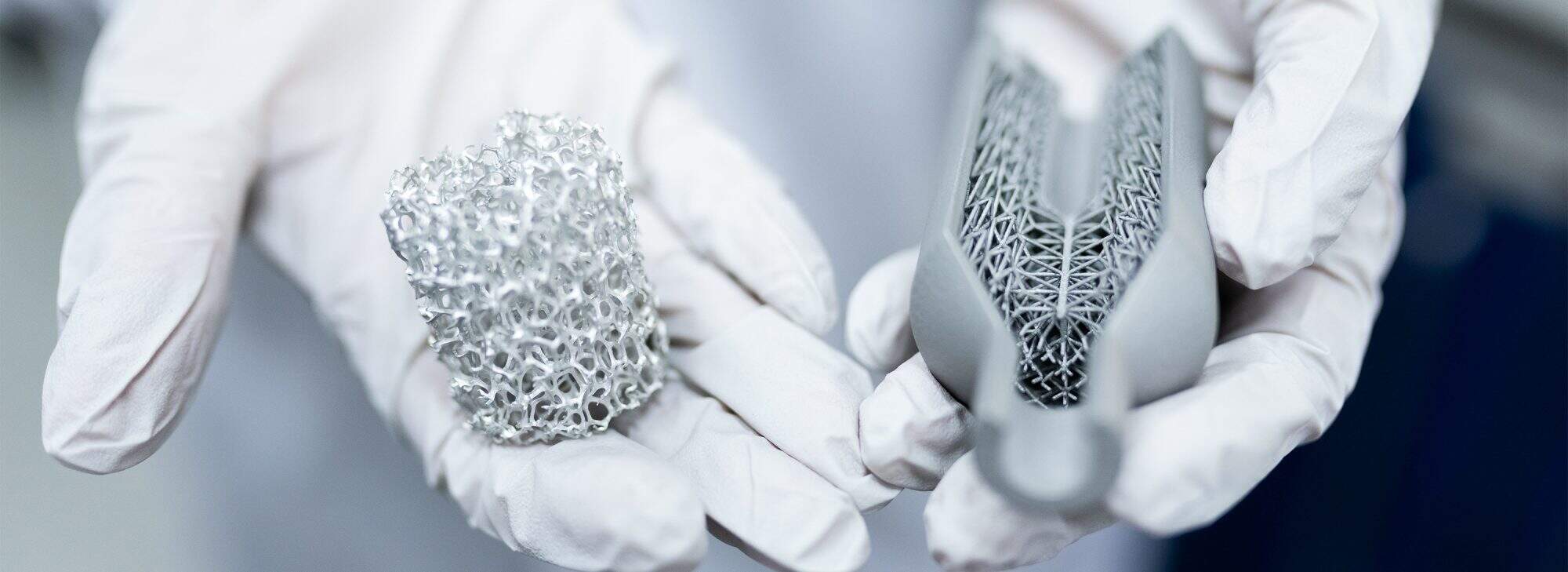

C103 for Additive Manufacturing

We proudly offer C103 powder tailored for diverse AM technologies that optimize high-performance outputs. With its remarkable ability to maintain strength at temperatures up to 2,700 °F (1,482 °C), C103 powder is exceptionally suited for demanding applications across industries.

Additionally, the unique properties of C103 powder, makes it ideal for additively manufactured implants that utilize niobium alloys. They exhibit superb mechanical properties and biocompatibility, further enhancing their utility across various industries.