C103 Additive Manufacturing

At Elmet Technologies, we leverage the exceptional properties of C103 to revolutionize additive manufacturing from our facility in Coldwater, Michigan. This state-of-the-art process significantly reduces production time compared to traditional methods while enabling the creation of highly customized components through advanced 3D printing technology. Our C103 additive-manufactured parts stand out by offering nearly twice the strength and substantially improved creep resistance at high temperatures, outperforming their conventionally processed alloy counterparts.

Manufacturing for the Future

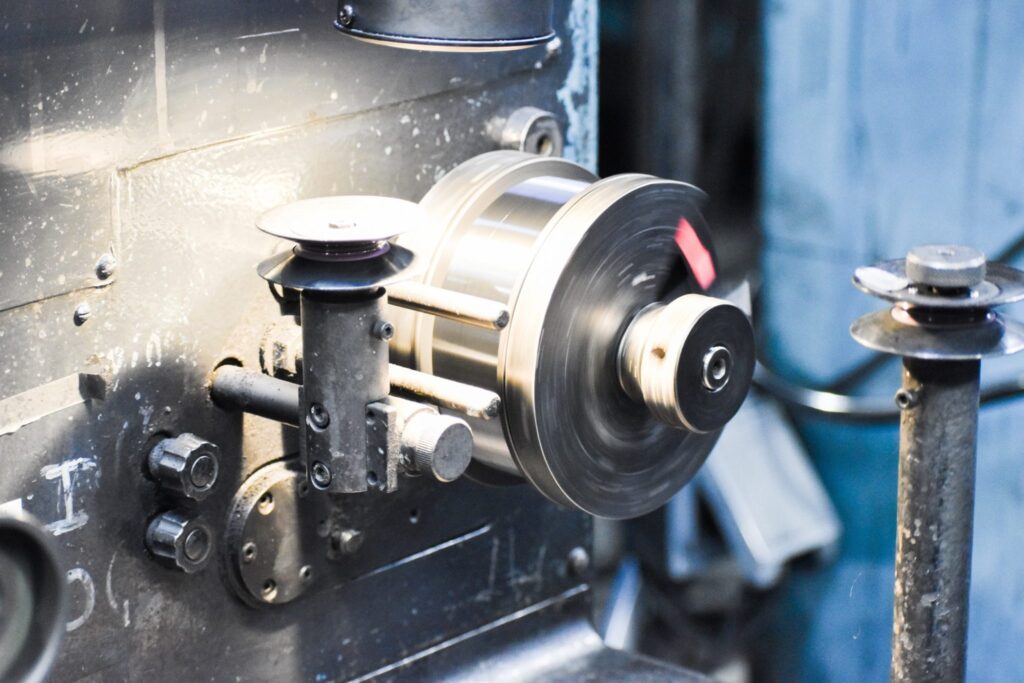

At Elmet, we actively invest in state-of-the-art Additive Manufacturing (AM) technologies, such as the Renishaw Laser-Powder Bed Fusion printer, to enhance our expertise in niobium alloy production. As a result, we strive to greatly broaden the spectrum of products and services we offer to the AM industry.

C103 for Additive Manufacturing

Due to its unique properties – high melting points, high corrosion resistance, excellent chemical resistance, and high thermal and electrical conductivity – Nb alloys are suitable for a wide range of high-tech applications:

- Chemical

- Superconductors

- Chemical processing industries

Additively manufactured implants using specific alloys containing niobium provide excellent performance due to their superior mechanical properties and high levels of biocompatibility.

c103 AM Printed Parts

At Elmet Technologies, we’re advancing additive manufacturing with C103. Our expertise in crafting custom powders and optimizing printing parameters allows us to create high-density refractory metal components. We can produce printed parts up to 10x10x10 inches for various applications.

We showcase our commitment to innovation through the use of C103, a material that has become essential in the aerospace industry. C103 improves feasibility and design flexibility by removing the limitations typically associated with bar stock sizing.

Benefits of C103 in Additive Manufacturing

- Streamline Production: Consolidating multiple assemblies into one cohesive part to reduce complexity and enhance efficiency.

- Component Performance Boost: Optimizing properties of existing components creates unmatched performance and durability.

- Lightweight Solutions: Producing lighter parts and assemblies increases efficiency and reduces overall material usage.

- Tailor Customization: Access a diverse range of metals to meet specific project requirements and specifications.

- Accelerate Development: Quicker prototyping and iteration processes to fast-track product development cycles.

- Eco-friendly Manufacturing: Minimized material waste in manufacturing processes.

- Optimize Inventory: Reduce inventory needs with on-demand production capabilities.

- Energy-Efficient Production: Lower energy consumption provides an environmentally conscious manufacturing option.

- Versatile Production Capacity: Either high-volume or low-volume production is supported, providing necessary flexibility.

revolutionizing 3D printing with l-pbf

Laser–Powder Bed Fusion (L-PBF) stands out as a leading technique in additive manufacturing for metal components. This method enables the creation of diverse parts by utilizing layers of spherical metal powders that are expertly melted and fused with a laser. The resulting parts boast full density, precise dimensions, and superior surface finishes. Notably, L-PBF excels in producing components with intricate geometries and allows the use of materials straight in their printed form.

Through the use of L-PBF, Elmet is at the forefront of innovation. Our state-of-the-art Renishaw L-PBF printer exemplifies the future of 3D printing by ensuring precision and quality in every part we produce. We supply the chemical composition of finished parts upon request when a purchase order is placed, ensuring transparency and satisfaction.

Market Use for Additive Printing

Elmet’s 3D printing solutions support customers across key end markets, providing distinct advantages. We continuously broaden our portfolio to design and refine parts specifically for applications in markets previously unfamiliar with the use of refractory metals. By embracing this cutting-edge technology, we empower businesses to unlock new possibilities and enhance performance in their respective industries.

Markets that benefit from AM are primarily aerospace and defense. The medical, industrial, and nuclear industries can also benefit by overcoming the limitations of traditional methods, customizing tools, or enhancing material strength.

Innovation in additive manufacturing

As the reach of additive manufacturing continues to expand across industries, our ongoing research into new applications for C103 allows us to actively participate in designing cutting-edge solutions. Transitioning seamlessly between innovation and application, Elmet Technologies leads the charge in advancing AM capabilities, ensuring our partners stay ahead in an ever-evolving market landscape.