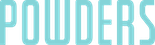

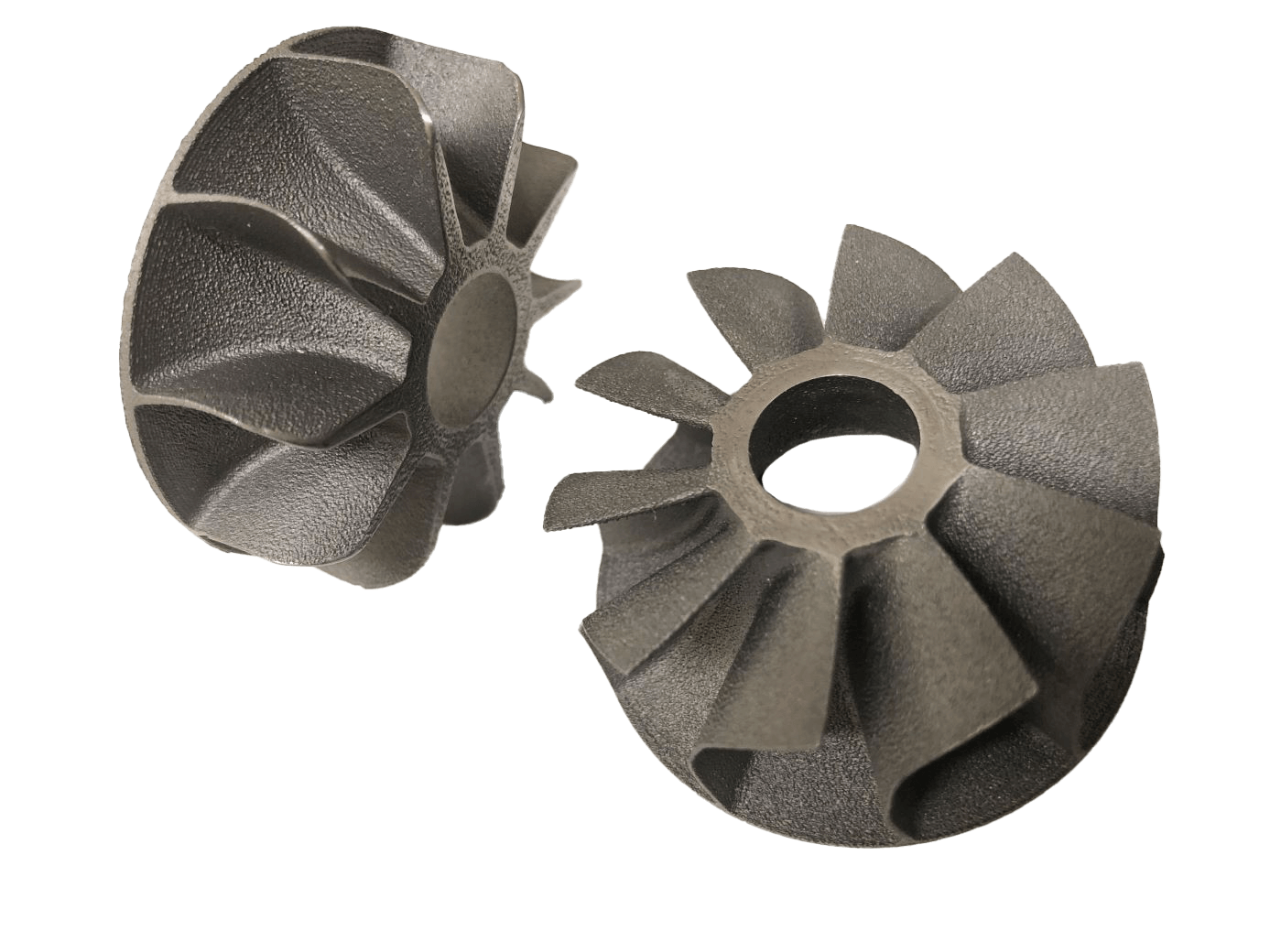

C103 AM Printed Parts

Elmet Technologies leverages the versatility of C103 bar, rod, and powder to produce advanced AM printed parts with exceptional precision and performance.. With expertise in crafting custom powders and optimizing printing parameters, we manufacture high-density refractory metal components tailored to meet the needs of various industries, including aerospace, medical, and energy.

By harnessing the innovation of 3D printing, we proudly offer a highly efficient and precise method for fabricating gradient structures with complex geometries, enabling new design possibilities and enhanced material performance. This approach unlocks significant potential for the large-scale production of gradient-structured metals and alloys, paving the way for applications that demand both durability and intricate design in high-performance environments.

Transforming Additive Manufacturing with C103

The integration of C103 in additive manufacturing has transformed the aerospace industry, delivering enhanced feasibility and unparalleled design flexibility while overcoming the limitations of traditional bar stock sizes. Our 3D printing solutions empower customers across diverse sectors, including aerospace, defense, medical, industrial, and nuclear.

At Elmet Technologies, we are committed to expanding the boundaries of innovation. By continually broadening our portfolio, we design and develop parts for industries yet to fully explore the potential of refractory metals, ensuring our clients benefit from cutting-edge, customized solutions.

Expert Manufacturing

We turn our metal powders into advanced finished products using optimal additive manufacturing methods.

Reliable Partnerships

We are able to support multiple AM projects with a refractory metal parts portfolio covering all key markets.

Innovative Methods

We focus on the laser-powder bed fusion method, a prominent method in AM for metal components.

C103 Powder in Additive Manufacturing

Elmet Technologies meticulously manufactures powders to meet the high standards of additive manufacturing methods. The characteristics of C103 powder surpass conventional production specifications and provides enhanced performance.

Properties of C103 Powder:

- High purity

- High bulk density

- Spherical powder morphology

- Exceptional flowability

- Low oxygen

- PSD optimized for specific printing methods

Producing Additive manufacturing Printed Parts

- C103 is printed using additive manufacturing.

- Laser-Powder Bed Fusion produces printed parts.

- We use extrusion and rotary forging methods.

- AM powder is used with US-based external vendor partnerships.

- Using C103 powder, we print 3D parts in-house.

- We offer machined C103 bar and rod.

Laser-Powder Bed Fusion

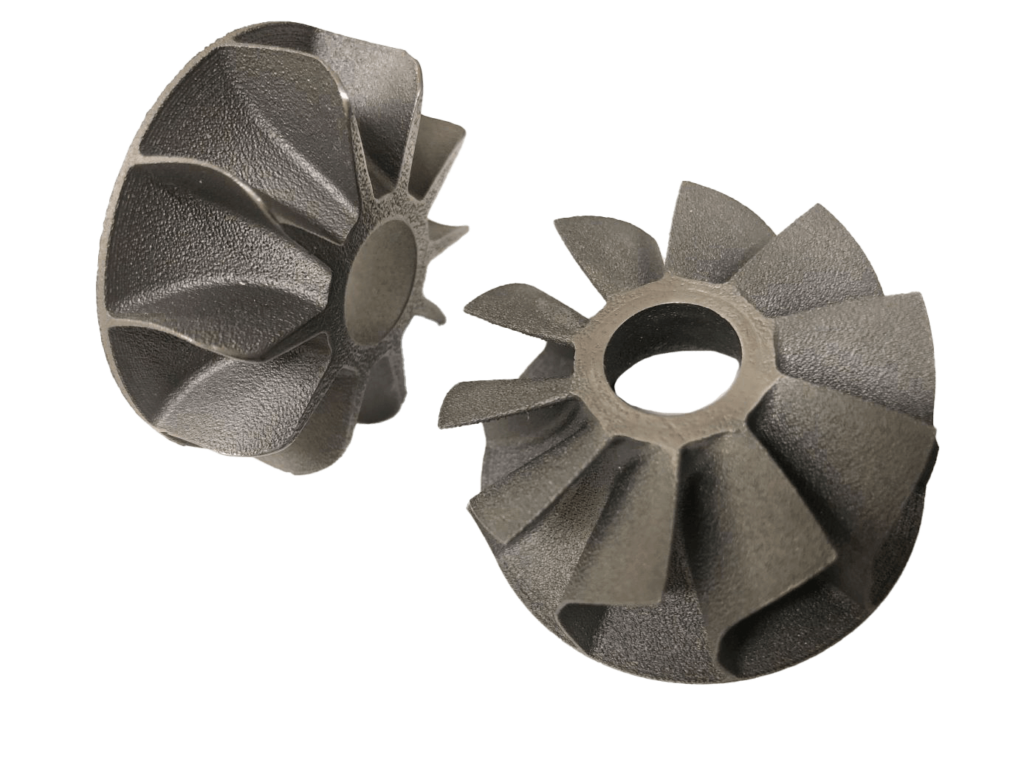

Elmet is advancing 3D printing with the Renishaw Laser-Powder Bed Fusion printer located in our Coldwater, Michigan facility. This technology enables precise use of high-performance materials like niobium, tungsten, rhenium, and molybdenum. This printer brings complex designs to life using durable and reliable materials that push the limits of 3D printing and expand possibilities for innovative projects.

- Printing of custom alloys in small batches through the reduced build volume (5-10kg)

- Maintains optimal material integrity with <100 ppm oxygen in the build chamber

- Build Volume: 250 x 250 x 280 mm (9.8 x 9.8 x 11 in tall)

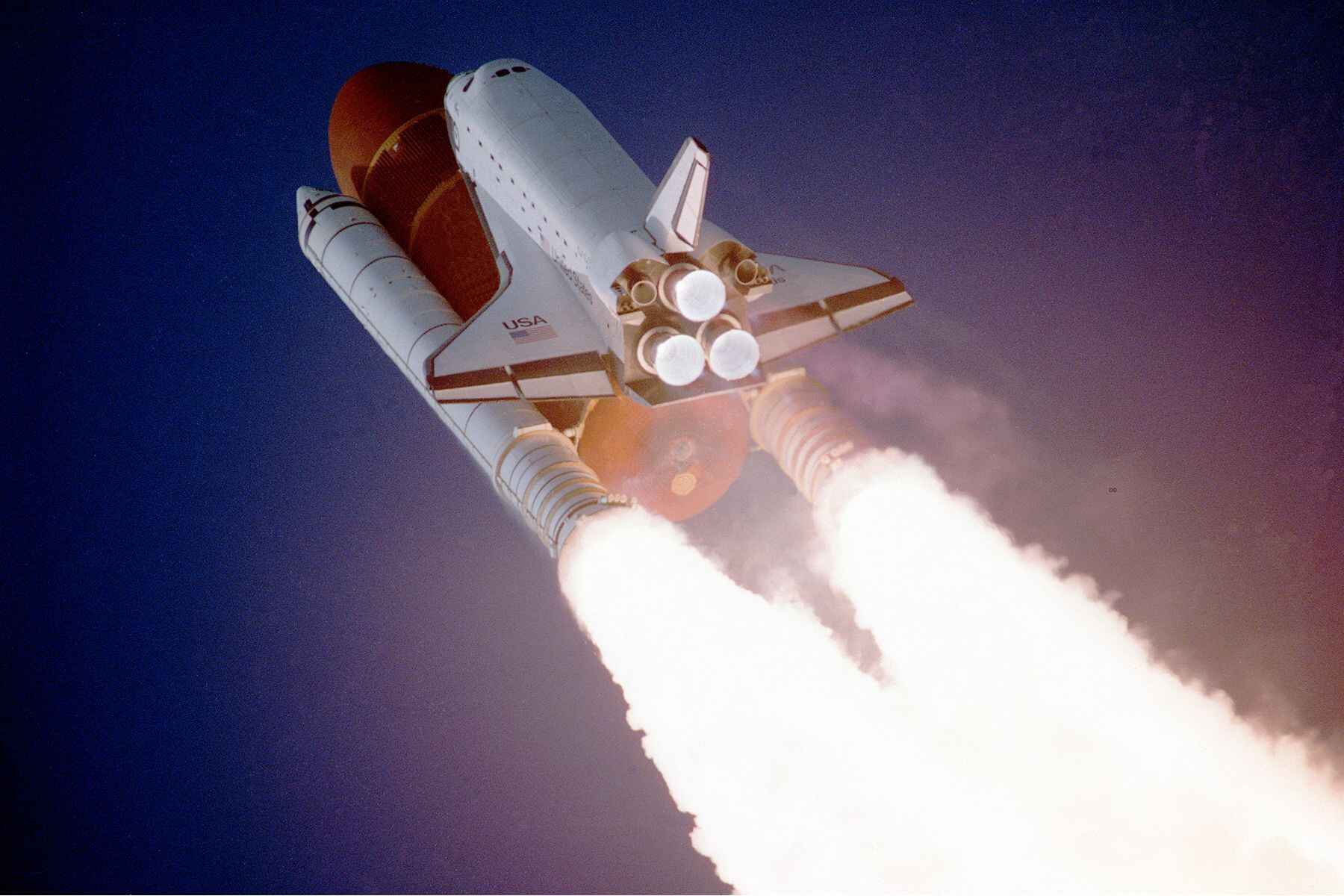

3D Printing for Space Travel

When it comes to constructing 3D-printed thruster nozzles for rockets, C103 plays a pivotal role. Rocket propulsion systems require materials like C103 to endure the intense heat experienced during launch. It becomes essential when regenerative cooling isn’t viable, or when there is a need for simplified component designs.

Additionally, for propulsion systems intended for deep space exploration, C103’s lightweight nature makes it ideal for creating components that can resist the harsh conditions of lunar and deep space environments. As aerospace technology advances, the adoption of C103 in 3D printing processes represents a significant step in enhancing the performance and durability of rocket components.

Shaping the Future with Additive manufacturing

Advantages of Additive Manufacturing:

- Intricate forms can be made straight from CAD models that would otherwise be impossible to fabricate, resulting in lightweight, refined designs.

- Printing customized medical parts that fit an individual’s anatomy perfectly results in highly accurate biocompatibility.

- By consolidating printed components, we see efficient production, reduced inventory, and overall improved reliability.

- Controlling the microstructure of metals during manufacturing enhances mechanical properties.